Built for Depth and Impact: How ESC’s Trench Boxes Surpass the Competition

- ESC Trench Shoring Inc.

- Nov 22, 2025

- 7 min read

When trench conditions shift, regulations alone won’t protect your crew. ESC’s trench boxes are engineered for extremes—because real-world excavation rarely plays by the book.

Most trench boxes are built to meet OSHA standards. That’s the bare minimum. But what happens when soil shifts mid-dig? When does water seep overnight? When does your trench go deeper than expected?

ESC doesn’t just build compliant trench shields. We build trench protection systems that hold up when conditions turn unpredictable—because that’s when lives are on the line.

Why ESC Is the Smarter Choice for Serious Projects

ESC’s trench boxes are designed for contractors, engineers, and agencies who need more than a checkbox solution. Here’s what sets them apart:

Fully welded panels—no stitch welds, no shortcuts. That means maximum strength across the entire shield.

Depth-rated up to 40 feet, certified by third-party engineers. Ideal for deep utility work, sewer lines, and emergency excavation.

Knife-edge and flat-bottom options for better soil penetration and stability.

Custom sizing and spreader configurations to match your site—not force your site to match the box.

These aren’t just specs. They’re answers to the questions your crew asks when the trench gets deeper, wetter, or riskier than planned.

The Competitive Landscape: What Others Offer—and What They Miss

In the U.S. trench safety market, contractors often face a familiar lineup: aluminum trench boxes and generic steel shields that appear to “do the job.” But dig deeper—literally—and the differences become costly.

Common Options in the Market

Lightweight and easy to handle but limited in depth ratings and prone to flexing under pressure. Suitable for shallow digs, but risky for anything beyond basic utility work.

Often mass-produced with stitch welds and inconsistent steel grades. They meet minimum standards but lack the structural integrity needed for deeper or high-risk excavations.

What’s missing? Depth ratings that go beyond 16 feet. Modular flexibility for complex trenching. And engineering support when conditions change mid-project.

ESC fills those gaps—with trench boxes that are certified up to 40 feet, fully welded for strength, and backed by real engineering expertise.

ESC’s Competitive Advantage: Engineered to Outperform

A. Strength and Depth Ratings - When the trench goes deeper, ESC doesn’t flinch.

ESC’s trench boxes are built for serious depth and serious pressure. Reinforced panels, high-grade steel, and precision welding deliver the kind of strength that holds up in unpredictable soil and high-load conditions. With depth ratings up to 40 feet, these shields aren’t just compliant, they’re built for the realities of deep utility work, emergency excavation, and municipal infrastructure.

B. Modular Efficiency - Time is money. ESC saves both.

ESC’s modular trench box systems are designed for fast setup and teardown—without compromising safety. Custom spreader options and stackable configurations help crews adapt quickly to changing trench dimensions. For contractors juggling tight schedules and complex sites, ESC’s modular efficiency means fewer delays and smoother installs.

C. Support and Customization - No two trenches are alike. ESC builds accordingly.

ESC’s in-house engineering team works directly with contractors and agencies to design trench boxes that match your site’s specific challenges. Whether it’s a tight urban dig or a sprawling infrastructure project, ESC offers custom builds and technical support that go beyond the catalog. It’s trench protection tailored to your reality.

Side-by-Side Comparison: Why ESC Delivers More Than the Standard

For procurement teams comparing trench protection systems, specs alone don’t tell the full story. ESC’s trench boxes are engineered for real-world excavation—where depth ratings, material integrity, and long-term value matter more than marketing claims. Here’s how ESC stacks up against typical competitors:

Feature | ESC Trench Box | Typical Competitor |

Depth Rating | Up to 7m+ | 3–5m |

Panel Strength | High-grade steel | Mixed alloys |

Modularity | Fully stackable, adjustable | Limited options |

Engineering Support | Included | Rare or extra cost |

Longevity | Multi-year durability | Frequent replacement |

Procurement Insight:

Depth rating matters for sewer lines, emergency digs, and federal infrastructure projects.

Material quality affects long-term safety and repair costs.

Modularity speeds up installation and adapts to changing trench dimensions.

Engineering support ensures compliance and confidence during submittals.

Durability reduces replacement cycles and total cost of ownership.

Proven Performance in the Field

Across the U.S., contractors and agencies are making the switch to ESC trench boxes—and the results speak for themselves.

One Midwestern utility contractor faced daily delays due to mismatched trench shields and slow assembly. After switching to ESC’s modular trench box system with custom spreader configurations, they reduced setup time by 40%, allowing crews to trench faster and reclaim lost hours. For procurement teams managing tight schedules, ESC’s modular efficiency translates directly into cost savings and smoother operations.

In the Southeast, a city infrastructure project ran into trouble when deeper trenching was required for sewer upgrades. The competitor’s boxes couldn’t meet the depth requirements, threatening delays and redesigns. ESC stepped in with trench boxes certified to 40 feet, backed by third-party engineering. The project stayed on track, passed review, and avoided costly setbacks. When depth matters, ESC delivers more than compliance—it delivers confidence.

Meanwhile, a civil engineering firm overseeing multi-phase roadwork had grown frustrated with frequent replacements of underperforming trench shields. They invested in ESC’s fully welded, high-grade steel trench boxes and saw a dramatic shift in long-term value. Over three phases, the firm reported zero replacements and lower total cost of ownership. For agencies and contractors managing long-term infrastructure work, ESC’s durability isn’t just a feature, it’s a financial advantage.

ESC’s trench protection systems aren’t just built for depth and impact—they’re built for real-world wins. If you’re evaluating trench boxes for your next bid, ESC offers more than specs. It offers certainty.

Choosing the Right Shield: What ESC’s Product Line Reveals

ESC’s trench shoring systems aren’t one-size-fits-all. They’re engineered to match the realities of excavation across a wide range of applications:

ESC’s trench shields are the backbone of serious excavation. Built from high-grade steel and fully welded for structural integrity, these shields are engineered to withstand the lateral pressures of deep trenches, heavy equipment, and unstable soils. With depth ratings up to 40 feet and third-party engineering certifications, they’re ideal for sewer installations, water mains, and emergency response work where failure isn’t an option. These are not commodity boxes—they’re engineered protection systems designed for long-term use and repeat deployment across multiple job sites.

Aluminum Trench Shields - For shallow digs and tight-access sites.

When maneuverability matters, ESC’s aluminum trench shields offer lightweight strength without compromising safety. These shields are easy to transport, assemble, and reposition—making them ideal for utility crews working in residential neighborhoods, urban corridors, or areas with limited equipment access. While not designed for extreme depths, they’re perfect for shallow trenching, service line repairs, and quick-turnaround projects where speed and flexibility are key.

Manhole Boxes - For vertical access and confined installations

ESC’s manhole boxes are purpose-built for vertical excavations where traditional trench shields fall short. Designed to provide 360-degree protection around confined spaces, these systems are essential for installing or maintaining manholes, vaults, and lift stations. With removable panels and corner posts, they allow for safe entry and exit while maintaining structural support. For municipalities and contractors working in tight urban grids or utility corridors, manhole boxes offer a safer, smarter alternative to improvising with standard shields.

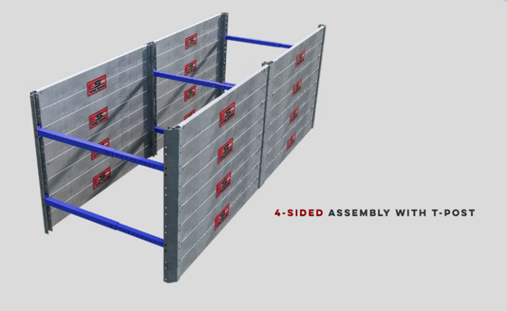

Modular Systems - Adaptable trench protection for changing site conditions

No two trenches are alike—and ESC’s modular systems are built with that in mind. These stackable, adjustable trench boxes allow crews to adapt quickly to changing trench widths, depths, and soil conditions. Whether you’re working around existing infrastructure or expanding a dig mid-project, ESC’s modular designs reduce downtime and eliminate the need for multiple shield types. They’re also easier to transport and store, making them a practical choice for contractors managing multiple sites or phased projects.

ESC offers a range of spreader bars and telescopic struts that allow trench boxes to be configured to exact site dimensions. Whether you’re working with a mini-excavator or a full-size backhoe, ESC’s spreader solutions ensure your shield fits the trench—not the other way around. This flexibility improves safety, reduces over-digging, and speeds up installation. For procurement teams, it also means fewer change orders and better alignment with project specs.

Bedding Boxes and Trench Sheets - Supporting excavation and backfill with efficiency and control

ESC’s bedding boxes streamline material handling by keeping bedding aggregate contained and accessible at the trench edge. This reduces waste, minimizes cleanup, and improves crew productivity. Trench sheets, on the other hand, provide temporary shoring for narrow or irregular excavations, especially in soft or collapsing soils. Together, these tools support safer, cleaner, and more efficient trenching operations—particularly on linear utility runs and infrastructure upgrades.

Every product is available for sale, and every system is backed by ESC’s in-house engineering team. Whether you're working in Type A, B, or C soil—or dealing with groundwater, overhead obstructions, or adjacent structures—ESC helps you match the right shield to your site.

Built to Win, Not Just to Work

ESC doesn’t build trench boxes for ideal conditions. We build for the moments that test your crew, your timeline, and your reputation. When the trench gets deeper, wetter, or riskier than expected, ESC’s systems hold up—because they’re engineered for impact.

Our commitment goes beyond compliance. It’s about delivering trench protection that performs under pressure, adapts to real-world challenges, and adds long-term value to every project. From fully welded steel panels to modular configurations and in-house engineering support, every ESC system is designed to help you win bids, meet deadlines, and protect your team—job after job.

If you’re comparing trench boxes, don’t just look at specs. Look at outcomes. Look at the crew who’ve made the switch and never looked back. Look at the projects that stayed on track because ESC was in the ground.

Download our spec sheet or request a competitive analysis to see how ESC stacks up for your next project.

Website: www.esctrenchshoring.com

·Phone: +1 (980) 689 4388

Email: info@esctrenchshoring.com

CORNELIUS, NORTH CAROLINA Office

20109 Knox Road, Cornelius,

North Carolina 28031, USA

DISTRIBUTION YARD

2185 Salisbury Highway, Statesville, North Carolina, 28677, USA

MANUFACTURING FACILITY

2231 Old Wilkesboro Road, Salisbury, North Carolina, 28144